The specialized maintenance demands of modern hybrid airships require purpose-built Airship Engine Stands Lease solutions that address their unique propulsion systems. Unlike conventional aircraft, these lighter-than-air hybrids combine traditional gas lift with vectored thrust engines positioned at unconventional angles and configurations. This creates specialized handling requirements that standard aviation equipment simply cannot accommodate effectively or safely.

For maintenance operations seeking flexible equipment solutions, airship engine stands for lease providers are now developing custom options specifically engineered for next-generation airships. Industry leaders like https://stands.aero/product/leap-1b/ have begun adapting their extensive aerospace expertise to the emerging airship sector, creating customized support equipment that addresses the unique maintenance challenges these hybrid craft present.

The Unique Engineering Challenges of Hybrid Airship Maintenance

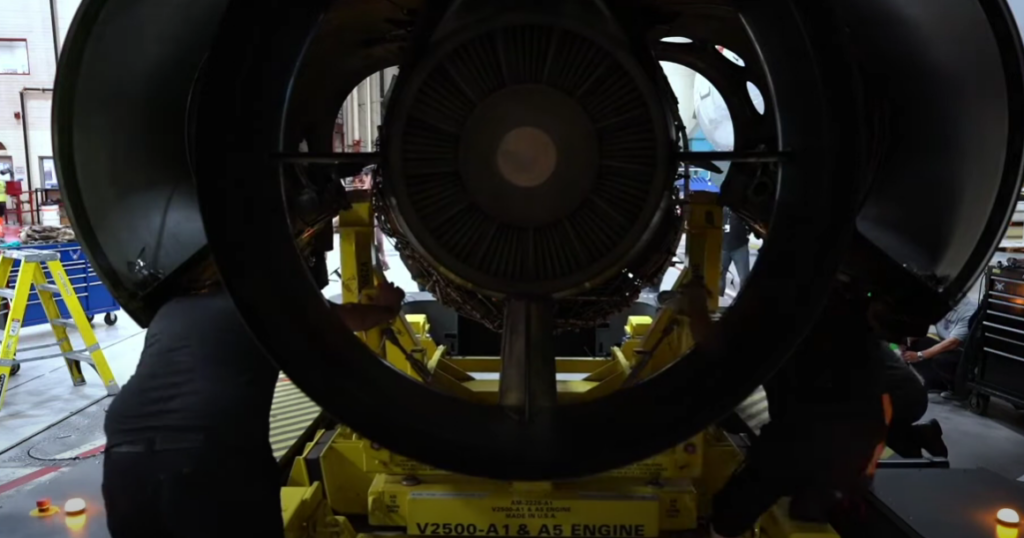

Modern hybrid airships incorporate propulsion systems that differ significantly from conventional fixed-wing aircraft, creating specialized requirements for maintenance equipment. These differences demand innovative approaches to engine support systems during maintenance operations.

Critical Design Considerations

The physical configuration of hybrid airship engines requires completely different approaches to mounting, balance, and access compared to traditional aircraft engines. These unique characteristics create several engineering challenges:

- Unconventional mounting angles requiring multi-axis adjustability

- Lower weight but larger diameter engine configurations

- Integration with envelope systems requiring specialized access

- Vector thrust components that must be maintained in specific orientations

Customized Stand Features for Next-Generation Airships

The latest generation of airship engine stands incorporates innovative features specifically designed to address the unique requirements of hybrid propulsion systems. These specialized stands enable maintenance operations that would be impossible with conventional equipment.

Advanced Engineering Elements

Today’s custom airship engine stands incorporate several critical innovations that make them suitable for these specialized applications:

- Lightweight composite materials reducing overall stand weight while maintaining structural integrity

- Multi-axis adjustment systems allowing precise positioning regardless of engine orientation

- Modular design elements that adapt to different engine variants

- Enhanced mobility systems for maneuvering in hangar environments with fabric envelopes

- Specialized protective features to prevent damage to sensitive composite components

Comparison of Airship Engine Stand Types

The market now offers several specialized stand options designed for different classes of hybrid airships. Understanding the distinctions between these systems helps maintenance operations select appropriate equipment for specific craft types. The following table outlines key differences between major stand categories:

| Stand Type | Suitable Airship Class | Weight Capacity | Adjustment Axes | Special Features | Typical Lease Cost (Monthly) |

|---|---|---|---|---|---|

| Vectored Thrust | Small Hybrids (15-30m) | 900-1,500 lbs | 3-axis | Compact footprint, trailer transportable | $4,500-$6,500 |

| Ducted Fan | Medium Hybrids (30-60m) | 1,500-3,000 lbs | 5-axis | Enhanced height adjustment, stabilizing outriggers | $7,000-$9,500 |

| Integrated Propulsion | Large Hybrids (60m+) | 3,000-5,000 lbs | 6-axis | Computer-assisted positioning, remote control capability | $12,000-$18,000 |

| Multi-Engine Array | Military/Heavy Lift | 5,000-8,000 lbs | 6-axis + rotational | Synchronized multi-point lifting, reinforced structure | $20,000-$30,000 |

Financial Advantages of Leasing for Specialized Operations

The economic case for leasing airship engine stands is particularly compelling given the specialized nature of the equipment and the emerging state of the hybrid airship market. This approach creates significant financial advantages for operators and maintenance providers alike.

Cost-Benefit Analysis

Leasing specialized airship engine stands provides several financial benefits compared to outright purchase, especially for operations that service multiple craft types or have intermittent maintenance schedules. These advantages include:

- Elimination of large capital expenditure for highly specialized equipment

- Access to the latest technology as stands evolve with rapidly developing airship designs

- Reduction in specialized storage requirements between maintenance cycles

- Transfer of certification and compliance responsibilities to the leasing provider

- Flexibility to scale equipment needs based on current maintenance volume

Logistics Considerations for Specialized Equipment

The physical characteristics of airship engine stands create unique logistics challenges that must be addressed when planning maintenance operations. These considerations impact both on-site operations and the transportation of stands between facilities.

Shipping and Deployment Planning

Modern airship stand leasing providers have developed specialized logistics solutions to address the unique requirements of these oversized components. When planning for stand delivery, maintenance operations should consider:

- Oversized transport requirements for larger stand components

- Assembly space needs within hangar facilities

- Integration with existing handling equipment

- Specialized training for technicians unfamiliar with airship-specific equipment

- Lead time requirements for custom configuration adjustments

Frequently Asked Questions

What makes airship engine stands different from conventional aircraft stands?

Airship engine stands feature multi-axis adjustment capabilities to accommodate unconventional mounting angles, lightweight construction compatible with airship structures, and specialized protective features for composite components. They’re engineered specifically for the unique thrust vectoring systems and non-standard positioning found in hybrid airships.

How far in advance should I arrange an airship engine stand lease?

For standard configurations, 4-6 weeks advance notice is typically sufficient. However, highly specialized or custom-modified stands may require 8-12 weeks lead time. Many providers offer expedited options for urgent maintenance situations at premium rates.

Do airship engine stand leases include technical support?

Most reputable leasing providers include 24/7 technical support as part of their standard lease agreements. This typically covers assembly guidance, operation training, and troubleshooting assistance. On-site technical support is available from premier providers as an additional service.

Are these stands compatible with traditional airship hangars?

Yes, modern airship engine stands are designed with legacy facilities in mind. They feature adjustable footprints, doorway-compatible dimensions when disassembled, and specialized wheel systems designed for the unique flooring found in airship hangars, including both modern concrete and traditional wooden surfaces.

Emerging Industry Standards

As the hybrid airship sector continues to evolve, industry associations are working to establish standardized specifications for maintenance equipment. These developing standards will help create consistency across different stands while ensuring all safety and operational requirements are met.

The specialized nature of airship propulsion systems requires equally specialized maintenance equipment. Through strategic leasing partnerships, operators can access the custom-engineered stands necessary for safe, efficient maintenance without major capital investment. This approach provides the flexibility to adapt as airship technology continues its rapid evolution while ensuring maintenance operations have exactly the right equipment when and where they need it.